Whether you are a professional carpenter or a serious DIY person, having good wood lathes is

a must, if your works require to shape the wood into bowl, spindle, and vase form.

Then having a Lathe for woodworking comes really handy when it’s about making creative and artistic woodwork. However, choosing the best beginner wood lathe is a bit difficult as there are so many options that come with different specs and features.

So, considering your working requirement, you need to get the best wood lathe for the money. This article is packed with top 10 woodworking lathes that you can buy along with a buying guide section that will make it easy to focus on some specific features.

|

Image |

Name |

Editor’s Rating |

Price |

|---|---|---|---|

|

|

Delta Industrial 46-460 Midi Lathe |

5 out of 5 |

|

|

|

Shop Fox W1704 Benchtop Lathe |

5 out of 5 |

|

|

|

JET JWL 1221VS Wood Lathe |

4.5 out of 5 |

|

|

|

Nova 46300 Comet II |

4 out of 5 |

|

|

|

WEN 3420 Variable Speed Benchtop Wood Lathe |

4.5 out of 5 |

What Does a Wood Lathe Do?

A wood lathe is a machine that gives round and carved shapes to wooden pieces. It’s a must for making furniture and tableware. Wooden curved and rounded things that we see around us, such as a bat, baseball bat, are required to turn through wood lathes.

You can make carved wooden vessels as well as other items using such wood lathes. It works efficiently and saves precious time. You cannot carve and give a proper finish to an object by hand manually. Wood lathes ensure that the wood is properly carved, and the finish is top-notch.

A prefect wood turning lathe feature variable speed control that allows you to select a speed. You can choose a motor with variable speed ranges for finer tasks, and high speed for a comparatively aggressive task for your woodworking needs with lathes.

Our Best Wood Lathes Review For The Money

We have come up with the list of the top-notch wood lathe for beginners and experts considering top and popular models, real user reviews, and top recommendations from the experts. This is our list of the best overall wood lathes that range from full size to mini lathes, all with a powerful motor.

1. Delta Industrial 46-460 Tabletop Wood Lathe Machine

You know, great products comes from great manufacturer. Detlta one of the finest woodworking supply manufacturer in this industry. It offers lots of features with some attractive specs, and it seems perfect for professional woodworkers or carpenters.

This Delta industrial 46 460 tabletop wood lathe comes with 12-1/2 -inch swing capacity, which is one of the largest within its class. You will hardly find other mini wood lathe offer this much capacity.

Incase you don’t know, the swing capacity of a lathe is actually one of the most important parts of the device. The swing capacity represents how big or small of a workpiece can be used and worked with on wood lathes.

With its patented belt tensioning system for easy and quick speed changes and sets the belt at the correct tension every time for maximum power transfer and longer tool life. Additionally, midi lathes combine the power and performance of a full size lathe with the size convenience of a mini lathe.

For efficient operation, the mini lathe is powered by a 1 horsepower motor with 1725 rpm. The power is more than enough for works that require a more delicate finish without spending much time and effort

If a electronic variable speed range wood lathe is all you want, its three-pulley speed ranges will provide you with the necessary speed to turn any project. There is no need to change the belt position to change the speed rage; having a variable one is more convenient.

Electronic variable Speed with three-pulley speed ranges provide the required speeds needed to turn a project without changing belt position. The reversible electronic variable speed with a pulley system minimizes vibration and chatter.

The patented belt tensioning system allows easy and quick speed changes and sets the belt at the correct tension for maximum power transfer and longer tool life. It even has 6 inch tool rest and 10-inch tool rest, which is great for supporting a variety of turning applications.

If you are a woodworker or have some experience in the field, you would know that when you sand a turned piece with the grain, it will cause the wood fibers to lay down while making them rough.

But if you have this wood lathe, there will be no such issue. Its forward and reverse functions give a superior finish to the turner. It’s easy to achieve a smooth finish with a flip of the switch, which is great for a mini lathe.

To make the most out of your work, the mini lathe also offers a convenient belt tension system that allows you to change the speed much quicker. Furthermore, it also ensures that the belt is at its correct tension.

The bed is made from steel which allows the solid cast iron headstock to travel incredibly smoothly. The durable cast iron is the preferred material due to its well known longevity & strength.

As far as the durability is concerned, its cast iron construction makes it very durable, and enough stable with the faceplate, tools rest other turning applications.

As you’ll see in the cons, this wood lathe does not have a digital readout. It’s the only problem we found with lathe.

Pros

Cons

2. Shop Fox W1704 Benchtop Beginners Wood Lathe

This benchtop lathe performs best when it comes to tackling pen turning or shaping objects or other small cutting.

Like most other durable lathes on the market, Shop Fox manufactured the machine with cast iron, which assures you of its durability.

With 1/3 horsepower and 700 rpm to 3200 rpm speed, you can rely on the machine for smooth and optimal performance.

Although 1/3 horsepower might seem less convincing, trust me for doing smaller projects, you will find this one more than enough. You will be able to turn both hard and soft pieces of wood smoothly.

The lathe features a safety paddle switch, MT No. 1 live center, MT No. 1 spur center, 7 -inches, and 4-1/4 -inches tool rest, ¾ by 16 -inches TPI RH spindle, and 5-3/4 -inches faceplate for delicate operation.

This benchtop lathe includes a 5-3/4-inch faceplate which threads onto the headstock spindle for non-spindle turning. Like the previous one on our list, this lathe also offers a capacity of 12 -inches between its centers.

The capacity is pretty much a standard one compared to other products similar to it. Furthermore, an 8 -inches swing over the bed is also there as well.

Both the tool rests of this lathe come very handy when you do pen turning and other small projects. It’s designed this way to make the lathe an ideal one for doing such projects.

If you are looking for the best lathe for bowl turning, with the 5-3/4 -inches faceplate, the lathe works great for making bowls or objects of similar shape that you cannot get support from the tailstock.

Like most advance wood lathe, the W1704 model comes with a variable speed motor that allows you to adjust the speed according to your project’s requirement without re-adjusting the belt position.

Pros

Cons

3. JET JWL 1221VS Wood Turning Lathe

Among other models from the JET, this full size one is a bit different than others in terms of design and features of the wood lathes. If you previously used one of their lathes, this one will enhance your working experience for sure, especially with the digital readout for rpm.

The most exciting feature of this Jet JWL 1221vs lathe is its variable speed control. Although most lathes today come with variable speed control, you will not have the option to set extremely low speed. Its unbeatable speed control allows you to adjust the speed between 60 to 3600 rpm. You get the most appropriate speed for every project.

Not all the lathes available in the market feature a spindle lock. The manufacturer was kind enough to integrate a spring-loaded spindle lock for more convenient operation. You can also locate controls as well as DRO in a more efficient way. This spring-loaded spindle lock is integrated right into it.

For smooth and hassle-free operation, the lathe offers forward to reverse option. You will be able to give a superior finish to the working object effortlessly, because of the belt tension system.

The lathe also features an innovative ratchet style belt tension system. You can easily go for variable speed ranges by changing the belt. It also ensures that the tension is in the correct position.

For convenience, the manufacturer includes an Acme thread in the tailstock. Both the tailstock and banjo, slide pretty smoothly without putting much effort. This is something that not all lathes have.

Construction-wise, the lathe feels pretty solid, which means it can last you for years or even more. And as far as the stability is concerned, you will find it very stable and not making any disturbance when you work on it, even at 3600 RPM.

Pros

Cons

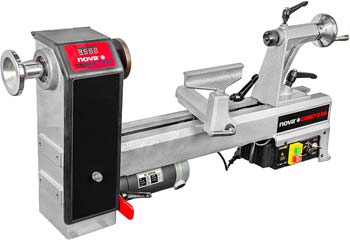

4. Nova 46300 Comet II

If a compact and portable lathe with great stability and features is what you are looking for, this mini lathe Comet II from Nova might grab your attention.

The machine offers variable speed control ranges from a very low to a high-speed option. Its 250 – 4,000 rpm speed allows you to work effectively on both large and small turnings. Also, the ability to forward and reverse switching allows you to achieve a superior finish on the objects.

The comet ii has a 3-step pulley system allows you to maximize the ability to work. The middle step will effectively deal with most woodturning applications. And rest 2 steps for more demanding applications.

You will have a 16.5-inches gap between both centers with 12-inches swing over bed, which means that is the very good distance between centers.

The capacity allows you to work on above-average objects very easily. The tailstock is very easy to adjust to accommodate various project lengths. It includes rear-mounted headstock and tailstock lock handles.

On top of that, you can expand the lathe up to 41-inches with a bed extension accessory. With the distance between centers being 12 inch makes this ideal for variety of turning projects. Having the 12 inch between the centers is very helpful.

The furniture makers find the 12-point index very convenient to use. They are easy to adjust and very accurate. It also has a locking system to make the head firmly locked into the position.

This lathe has cast iron construction for maximum strength. The machine feels pretty rigid and stays very stable while working. It’s designed to absorb vibration, as well.

Pros

Cons

5. WEN 3420 Variable Speed Benchtop | Best Wood Lathe for Beginners

Another wood lathe for turning bowls, non-spindle workpieces, and cups. With the variable speed anywhere between 750 to 3200 rpm, the lathe is able to handle your turning projects at ease.

You can adjust the speed with a simple speed knob whenever you need it. Whether you are making chess or something bigger than that, you will find this feature very convenient for your purpose.

WEN 3420 comes with a 5 inch faceplate and tool rests for making your turning projects more convenient. You can attach your workpieces of 12-inches long and 8-inches wide in between the centers.

The WEN Variable Speed Benchtop Wood Lathe features an MT1 spindle and tailstock taper to tightly grip workpieces. And it includes 5-inch faceplate for turning bowls, cups and other non-spindle workpieces. With that you can use workpieces up to 12 inches long and 8 inches wide.

This benchtop wood lathe comes with an MT1 and a spindle and tailstock taper that tightly hugs your workpieces and makes them more stable. The spindle and tailstock taper allows you to use a variety of accessories such as two tool rest, knockout rod, a tailstock cup center, a 5 inch faceplate, a headstock spur center, and more. The two tool rests and tailstock taper are great features.

Also, both of the tool-rests provide enough support to chisels and tools when you operate the machine through a 2A motor. It also includes a flat wrench, a headstock spur center, a tailstock cup center. You can even adjust the variable speed anywhere from 750 to 3200 rotations per minute

The 2A motor is powerful enough to turn most small to medium projects easily. It’s a slow start motor; this smart feature of the motor ensures your lathe starts safely and prevents damages.

When it’s about adjusting tool-rest and tailstock, you will find its lever clamps very easy to use to make the adjustment precise.

This is the best wood lathe for beginners on the list. If you are looking for a machine to turn small projects such as pens, chess, bowls, and goblets, you can consider getting it. As the price is hard to beat, it will add great value to your woodwork or hobby.

Pros

Cons

6. Mophorn 12 x 18 Bench Top Heavy-Duty Wood Lathe

This heavy-duty wood lathe is powered by a 550W motor, which is powerful enough to deal with turning works at ease. Like most other advanced lathes, this one also features a variable speed that ranges between 500 to 3800 rpm.

There is a digital reading display that helps to run your work with precise speed. This feature qualifies the machine to handle more delicate tasks that require precision.

The motor goes easy when you start it to ensure safety as well as minimize damage. You will find many reviews that state motor burns out with moderate usage. Such incidents happen due to a lack of safety measures. As this one starts slowly, there will be no motor burning issue because of it.

With this one, you will have 18 inch distance between two centers and a 10 inch swing capacity, 6 inch tool rest, and 3 -inches faceplate that allows you to load high capacity work without any trouble. Moving the lock lever to adjust or replace the tool rest makes this wood lathe great.

Most powerful lathes don’t provide enough stability, which can be a huge drawback for those who require to do more delicate work. Its sturdy cast iron construction and rubber feet provide superior stability and allow you to perform operations very smoothly.

Besides, all gears, as well as shafts within the headstock of this lathe, is securely grounded; thus, providing more stability and longer service life.

All the specs, as well as features, make it an excellent benchtop wood lathe to have to use in labs, engineering institutions, and workshops. It’s worthy of noting that few people have an issue with the tool rest.

Pros

Cons

7. PSI Woodworking KWL-1218VS Midi Lathe

Powered by a 1 x horsepower high performing induction motor along with SBC microprocessor, this midi lathe from PSI Woodworking is made for handling automotive applications. The lathe is able to deliver the user an exact control with reliable operation.

Each lathe on the list so far offers variable speed control with dual belt positions. With 500-1800 rpm, position A handles smaller tasks more efficiently. Similarly, position B with a variable speed motor – 1950-3800 rpm allows you to do a heavier task with great precision.

Therefore, whether you have to work on a small turning project or a larger one, the PSI woodworking wood lathes will enable you to do both without compromising the performance. It also features a 6″ tool rest, 12″ tool rest, 3″ Faceplate and a cast iron base.

As the lathe is able to deal with a heavier task, it also provides you with more working space to fit your working object between the centers.

There is an 18 inch space between the centers with 12-inches swing capacity .The Headstock and Tailstock Taper is #2MT and 24 indexing positions with spindle locking. Construction-wise the lathe feels pretty solid and stable due to its cast iron base.

Besides, you have option to expand the bed up to 42 -inches for giving space to larger projects at ease.

However, it may cause the motor to run a bit slower. But having this extensive option is very handy for larger larger projects.

Pros

Cons

8. Jet JWL 1440VSK Wood Lathe

Another wood lathe from Jet. The machine is a floor-standing model from Jet with a sturdy cast iron frame construction.

This one offers more power than the one we previously reviewed the same brand. Its powerful 1 HP motor allows you to work on wide bowl turnings, long and thick spindles, and aggressive cuts with ease.

With 400-3000 rpm variable speed control, it allows you to deal with a wide range of turning projects. You need to turn a knob to choose your preferred speed. However, there is no digital readout in the lathe that keeps the price relatively low compared to similar models.

There is an Acme thread on the tailstock, which you can quill lock using an anti-rotation key. The positive locking tool reset has a redesigned camp that’s CSA certified.

The sliding headstock is able to pivot 360 degrees and offers 7 convenient locking positions that ensure its variability as well as optimal user comfort. This allows you to work on smaller projects as well.

It also features a 14 -inches swing bed with a length of 40 -inches. The space it offers is perfect for turning table and chair legs and stair railing spindles. Also, you have the option to extend the bed up to 60 -inches between its two centers. So, for both small and large turning project, it’s the best wood lathe for turning bowls.

As the machine is designed for turning bowls, there is no reverse switching feature within it.

Pros

Cons

9. Laguna Tools Mlarevo 1836 Revo Lathe

If you want a more powerful wood lathe without compromising the price as well as most of the useful features, this lathe from Laguna tools can be a groundbreaking deal for you.

Let’s talk about its construction first. Laguna tools made no compromise with the material and made the lathe of sturdy and durable steel, which is an exception to all our previous wood lathe reviews. It allows the cast iron headstock to travel very smoothly.

The design will easily attract any passionate bowl turner. It’s ergonomic angled anodized aluminum made control panel will enhance your woodturning experience. The blue hue display, along with the beautifully designed knurled knob with rubber grip, looks absolutely stunning.

Its 2 HP induction motor is able to handle some serious turning projects with high efficiency. You have the option for variable speeds. For big turning projects, it offers a electronic variable speed 135-3500 rpm motor; and for low projects, it’s about 50-1300 rpm and a 220v 60hz single phase input.

You can do both small and precise projects as well as larger ones using the lathe with the electronic variable speed. This lathe even has a reverse switch and a 2 HP motor! This is the best wood lathe with a 2 HP motor that is on our list.

The long, low profile, and the tool rest is offset from the banjo which is incredibly thoughtful on Laguna’s part. You can use a short tool rest even if you can’t fit the banjo between the work and the bed because of this offset.

The mechanism of the lathe is able to convert single phase input to 3 phase output, which is obtained through a VFD. It has great torque even at pretty low settings. Additionally, the distance between centers is 36″, but the spring loaded spindle lock, has a outboard swing of 32″. Sliding headstock to accommodates smaller working areas or 32″ turning capacity with the optional bed extension.

Furthermore, DRO provides an accurate rpm readout, which is a must for making finer adjustments. You can change the setting using the quick release handle very easily.

Pros

Cons

10. RIKON Power Tools 70-220VSR Midi Lathe

This 1 horsepower midi lathe from Rikon Power Tools has everything you need for turning bowls, spindles, and platters of large size.

Most of the best lathes run on 1 HP motor. You don’t need to go for something higher than this in most cases. The dimensions are 12 x 40.75 x 18 inches that is the quite good for beginners wood lathe user.

Design and construction-wise, the lathe is heavier and more stable than a conventional mini-lathe. The stability of the machine is also very impressive.

You can work for turning larger objects with this lathe. With 20 -inches distance between centers and turning capacity of 12 ½ -inches swing bed, there will be no issue to fit a mid-size wood on the machine. Its 24 position index head makes it very convenient to cut the pattern of various projects.

Some lathes offer great variable speed while lacking reversible function. This isn’t the case if you get this 220VSR lathe. With its 250-3850 rpm speed ranges, you can do both delicate and aggressive turning projects. Also, the forward and reverse drive of the machine allows you to turn more than bowls and spindles.

There is an LED display that shows exact information about the speed; this also helps a lot while doing finer work. You can quickly switch between different speeds with easy access. It must be noted that for some projects the tool reset may get in the way.

Tools the lathe include are, spur center, 3 -inches faceplate, live center, tool rest, wrenches, knock-out bar, and tool holder, will enhance your bowl or spindle turning experience.

Pros

Cons

What to Look for before Buying?

Depending on your project type and your working requirement, you need to consider many factors when it comes to getting a wood lathe.

Project type

The very first consideration is to determine the type of project you are involved in. There are primarily two types of the wood lathe: smaller ones and full size larger ones. If you work on smaller objects such as bowls, chess, candle holders, etc. a small size wood lathe will serve your purpose the best.

On the flip side, larger lathes are for projects that involve larger objects such as table-chair legs, baseball bats, etc.

Also, consider whether you will expend your work field later when your skills improve, or you will stick to smaller objects. Smaller lathes have limited expansion feature but that will be enough for new users.

Size

Always remember, for lathes, bigger is better. Don’t fall for portable and compact models if you need to turn big projects. Having a large full sized lathe allows you to turn both small and big objects. However, if you get a small sized lathe, you only have to work with smaller objects.

If you have to work with heavier and thicker wood, then consider getting a larger full size lathe for superior support and strength.

Having a smaller lathe as a secondary turning machine seems fine. But don’t make a smaller one as your primary equipment.

If you are certain about your work that you will only deal with smaller objects and not go further, then you can get a small wood lathe for beginners. Otherwise you’ll need the full size lathe machine.

Speed

There are lathes offering manual and electronic speed option. The manufacturer restricts manual ones only to a few speed options. On the other hand, electronic ones provide a variety of speed for simple and full size heavier tasks.

A good lathes allow you to control the speed electronically, offer finer speed adjustments, and ensures you don’t ruin the wooden object.

Horsepower

Wood lathe machines are powered by a motor of different horsepower. It’s very simple and straightforward to understand that more horsepower is able to do operation more swiftly.

Most small to medium size lathes run on 1 HP motor that is very good for beginner users. As far as the full size machines are concerned, they mostly have 2 HP motor. More horsepower will allow you to do more turning work within less time.

Full size 2 HP wood lathes are best for large projects because its produce more strengths so you shapeup heavier wood easily.

If you are not professional and usually deal with light turning projects, 1 x HP will be sufficient for you. 2 HP suits the best for industrial projects.

Type

Lathes are either of table/bench top or free-stand. If you don’t have enough space to accommodate another machine in your workshop or garage, consider getting a table or benchtop lathe.

Tabletop lathes are great for easy and quick storage. If you are a person who occasionally uses a wood lathe machine, the tabletop is for you too.

For a professional, a heavy-duty, sturdy, and free-standing lathe suits the best. They are much durable than the bench ones. You can run a free-standing lathe for extended hours without worrying about durability and stability.

Stability

Some lathes shake a lot while operation, which feels very annoying. Look for a lathe that has solid heavy-duty, cast iron construction. The heavier the metal, the more stable the machine will be.

Lathes made of steel material are the best ones to get for stability. However, the price a lathe is much higher than the cast-iron ones. In our wood lathes review section, you will find both the type of machine.

Additional Features

The distance between two centers and swing over the bed; these two are very crucial features for any wood lathe. Swing over the bed determines the maximum thickness of stock that you can turn without striking the bed. On the other hand, the distance between the centers determines the maximum length of the stock.

The rest feature is also crucial as it’s associated with reducing the risk of injury in the workplace. You need to lock the tool rest to minimize the chance of possible danger. Some of them have a reverse switch, which is helpful.

What’s the Difference Between a Wood Lathe vs a Metal Lathe?

1. Applications

A wood lathe is used for building structures out of wood and a metal lathe is primarily meant for metalworking.

However, the latter can be used for other materials in addition to metals like steel, aluminum and iron. You can use them both to cut, drill, turn, deform and sand wood.

2. Portability

Wood lathe is much smaller and more lightweight than metal lathe machines. As a result, woodworkers can carry it around more easily for dynamic projects.

Metal ones on the other hand are too heavy to become a good portable option. You may find it hard to even move the metal lathe machine from one room to another!

3. Ease Of Use

Compared to metal lathe, wood lathe machines are much easier to use. The simpler structure makes it easier for the beginners to learn the details of woodworking and master the common moves. As a result, you can manipulate the pieces far more effectively with the wood lathe.

4. Precision

The reason behind the complexity of a metal lathe is its superior attention to precision. If you are someone who is just starting with wood but would like to upgrade to more accurate cuts in the future, you can switch to a metal lathe later. Comparatively, wood lathe fails to deliver a similar level of precision.

5. Speed

Along with offering a simpler structure and a favorable learning curve, wood lathe also seems to work a lot faster than metal lathe machines.

Working with metal takes a long time since it requires more attention and cutting through a metal is slightly harder than a piece of wood. That is why there are fewer revolutions per minute and thus a slower RPM speed ranges.

6. Cost

It comes as no surprise that wood lathe machines are much more affordable than a metal lathe. Besides, if you want to get super-creative and have tons of time in your hands, you can just make a wood lathe yourself!

However, developing a metal lathe can only be completed in an industrial setup since it requires a high level of precision in both designing and implementing.

Beginner Wood Lathe Using Guideline

1. Learn The Common Cuts

While the entire process of woodworking may seem intimidating to beginners, the steps and varieties of woodturning can actually be pretty easy to learn for them. Especially, there are some common cuts of woodturning which can be mastered in no time by the novice woodsmiths.

These cuts usually include lettering square, fillets, coves and V-grooves. Any amateur can learn them using wood lathe and about three or four other tools. After being accustomed to these common cuts, you can get creative with your projects and turn the workpiece into a spindle in any way you want!

2. Set Up Proper Lighting

Lighting is usually considered to be an important factor in jobs like painting and photography. However, woodworking is actually also a creative area where lighting matters!

You need proper lighting while working with wood lathe to see the working details clearly. That is why you may need to set up a movable lamp in your workstation so that you can shine the light at different angles to see developing details.

3. Start With Softwood

For those of you who are just starting in the field of woodworking, it would be a better idea to start with softwood for using beginner wood lathe.

This kind of material will be easier to cut and modify, making the entire process more smooth for an amateur woodworker. You can learn the basic techniques less stressfully with it.

Buy if you have much more confidence and have big wood lathe then you can start with any type of wood.

4. Keep the Blades Sharp

The chisels of a wood lathe make it capable of shaping a raw workpiece or carving the exquisite designs on the piece. That is why their sharpness matters a lot for the success of this process. Remember to keep your set of chisels sharp so that you never have to blame them for a faulty design!

5. Make The Most Of Body Weight

One of the easiest tricks to adopt is to use your body weight in your favor while trying to make clean and smooth cuts on the piece of wood. You can do this by leaning in the elbows and bracing against your body. Then your weight can help to make the perfect cuts by letting you utilize your arm strength.

6. 90-Degree Angle Placement

If you are a complete beginner in woodworking, you should know the ideal angle to put your blades or tool bits at – 90 degrees!

Placing those bits on the tool-rest at a right angle away from yourself can protect you and others present there from being hit by the flying shavings.

Although, the more skills and cuts you master in this area, you will be able to carry out working with wood lathe safely at other angles as well.

7. Safety Measures

The most important and unanimously agreed upon tip for working with wood lathe is to take all necessary safety measures before starting the task.

It’s considered to be among the most harmless power tools, you should still take the possible injuries into account and prepare for them accordingly. All power tools are dangerous, but you have to be careful.

Of course, the essentials like eye goggles or full face shields come first on the list of safety gear haul.

The clothing needs to fit perfectly since loose or baggy clothes are more prone to getting trapped in the spinning lathe.

8. Use A Screwdriver For Removing Bark

If you using a completely raw piece of wood, you can get rid of the bark more smoothly and easily by using a cordless screwdriver. Completing this step using a roughing gouge can result in some injuries since the removed barks can fly off at high speed.

Benefits of Using Wood Lathe

1. Accuracy

One of the reasons behind wood lathe becoming a popular tool in woodworking is its accuracy. Compared to other easily accessible and affordable tools like chisel, wood lathe can curve the wood much more precisely. As a result, you can attain much more impressive and pronounced details with this machine.

2. Versatility

With the help of a single wood lathe, you can work on different projects and structures. It doesn’t pose much of a limitation in your crafts – be it size, shape or complexity. You can use this machine to make versatile pieces like toothpicks, candle holders, bowls etc.

3. Consistency

Among many challenges of investing time in woodwork, there is the possibility of ending up with an inconsistent pattern for the same design or product. A wood lathe can solve this issue by maintaining consistency throughout all the single phase of producing your patterns in a project.

4. Fine Finish

Those of you who are a little experienced in woodworking, can make the most of wood lathe machines by using them to ensure fine finish. As a result, you can impress your clients more often by providing them high quality and skillful creativity at the same time.

5. Adjustable Chiseling

You don’t have to stay stuck on the same shape or cutting pattern with a wood lathe of good quality. You can adjust the chiseling to create new shapes or designs. As a result, you can explore more facets of your creativity if you choose to work with wood lathe instead of other chiseling tools.

6. Easy To Learn

Compared to its contemporaries like a metal lathe, using a wood lathe is easier to learn. Its structure is simpler since this tool doesn’t involve as many working parts. As a result, it’s easier to fix and eventually use for carving out different wooden pieces which are both artistic and functional simultaneously.

7. Lightweight

A wood lathe is much lighter than other varieties of lathe machines. Because of its lightweight structure, woodworkers of any level can carry it around more easily. This is a major advantage if you work in a dynamic workspace where moving a machine often becomes a necessity.

8. Affordable

If you are running on a tight budget or to keep the business expenses at a minimum, wood lathe may be a better than most other machines. Even for the beginners who are only starting their woodworking adventures, getting a standard wood lathe can be the more affordable option.

9. Size

The size of the wood lathe is also important. If you don’t have room or the budget for a full size wood lathe, then a beginner mini wood lathe or a midi wood lathe is a fantastic alternative.

The full size wood lathe will have more function, but most people can get the job done with a mini wood lathe. If you can afford the full size wood lathe, it’s worth the investment.

Big-size wood lathes are for serious wood turning projects. They are normally utilized for industrial functions or people making lots of money from wood turning.

These full sized wood turning lathes will be best if you intend on turning larger chunks of wood or to get serious about the wood turning business.

How to Clean a Wood Lathe After Use?

1. Removing Dust And Debris

It is important to remove dust and debris after each use so that the wood lathe doesn’t get stuck because of such accumulated residual.

In addition to the easily visible dust and shavings, you will also need to wipe off the smaller debris materials present throughout the lathe machine.

You can use an air compressor or a vacuum to clean the parts which are a little tough to reach. No need to rush since cleaning them well is vital for proper functioning of the machine in future projects.

2. After Turning Green Wood

Green wood refers to the fresher pieces of wood which have been cut recently. Since their moisture content is not dried up by evaporation, they are a lot more fun to work on for any woodsmith.

However, cleaning up after turning green wood can become quite the hassle. On the other hand, leaving the moist wood in your wood lathe for a while can lead to rust formation. That is why, you need to use a rust remover meant for lathe machines to apply on the affected areas.

If the rust is too stubborn already, use a fine sandpaper instead and apply it to the respective areas.

Remember to keep the sandpaper away from wood bowls since the contact between it and fine metal dust may lead to oxidation.

3. Morse Tapers

There are two Morse tapers present in a standard wood lathe machine named headstock and tailstock. They both need to be cleaned each day that you use the machine to keep them properly secured and aligned. Any remaining debris can push the tapers out of their alignment and thus make turning ineffective.

You can clean up both the tapers easily by using either a toothbrush or a cleaner made for this particular job.

4. Drive Belt

A drive belt connects the headstock of your woodworking lathe to its motor. This belt needs to be cleaned up and checked for irregularities from time to time. For checking it, you will need to unplug the machine, open up the belt covers and inspect the belt by manually rotating it.

Frequently Asked Questions

1. How to Sharpen Wood Lathe Tools?

The easiest way to sharpen your wood lathe tools is by using a grinder. You need to grind the cutting edge of the tools. Put the tool in the socket to make it firm while sharpening, and move the edge back and forth to sharpen the edge evenly. Do the same on the opposite side of the tool, as well.

However, if the tool has a rolled cutting edge, you need to sharpen the outer side of the edge. When you are done, take a 220 sandpaper to remove the burrs from the inner edge of the tool.

2. How to Use Wood Lathe Chisels?

Mount the stock you want to turn. Then, bring the tool rest close to the stock; it shouldn’t touch the stock. Set a slow speed range for a finer finish.

Put the chisel on the tool rest while holding the handle with your hand. Gently touch the stock with the edge of the chisel and do it back and forth until you get your desired shape.

Different chisels are used for giving different shapes. But this is, basically, how you should use a chisel.

3. How to Make a Wood Lathe With the Drill?

You can use a drill machine like a lathe. To do that, you need to construct a mini lathe using wood. Sometimes these mini lathes are best for what you need.

There needs to be a place where the drill machine rests firmly, and you also need to make a tailstock to hold the object that you want to turn. To control the drill speed range, you can use a dimmer switch and link it to the drill.

You will find tutorials on YouTube with a diagram of the wooden lathe frame if you are interested in making one.

4. What Size Wood Lathe do I Need?

Depending on your project’s requirement, the size of the lathe will vary. If you have to handle larger projects and heavier woods, then consider getting a larger machine. Or if you are working on a smaller project, consider mini lathes.

But, if your projects require you to use small wood stock, a small size lathe will suffice.

5. Can a Wood Lathe Be Used for Metal?

It’s possible to turn a wood lathe into a metal one. If you don’t have any mechanical lathe, you can turn small pieces of metal brass, aluminum, and steel in your wood lathe.

Conclusion

Before you start turning, make sure you don’t wear loose clothing. Prepare the place near the lathe neat and clean so that nothing catches on the spinning area. Also, wear a dust mask and safety glasses if necessary.

Hopefully, after reading our best wood lathes for beginners, now, you know which one to pursue to bring the most out of your work. So make sure you choose one of the best from our list!

You Might be Interested:

- How to Build Wood Lathe at Home?

- How to Buy Used Wood Lathes?

- Where Can You Get Wood Lathe Online?