Both CNC and laser cutting are highly efficient in precise cuts. Not only will this provide you with desired results, but you will also be able to save a considerable amount of time along with that.

Whether you are working with steel or any type of metal for that matter, you can use any one of the techniques to get your job done efficiently.

Though their purposes are the same, they do have differences among them, one is dependent on a computer, and the other is on heat energy. This is only the primary aspect that makes them different. You will find out further clarifications from the following article.

So, do check it out to get a clear understanding between the two cutting techniques.

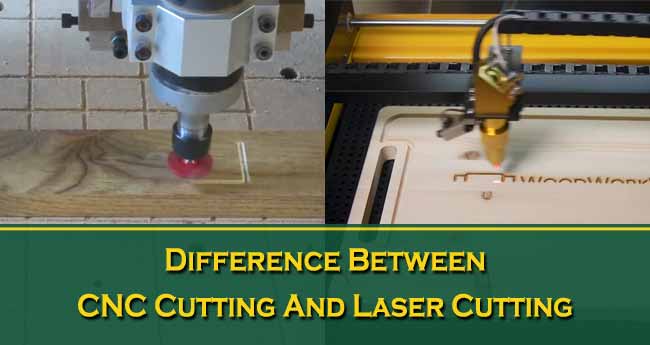

CNC Cutting

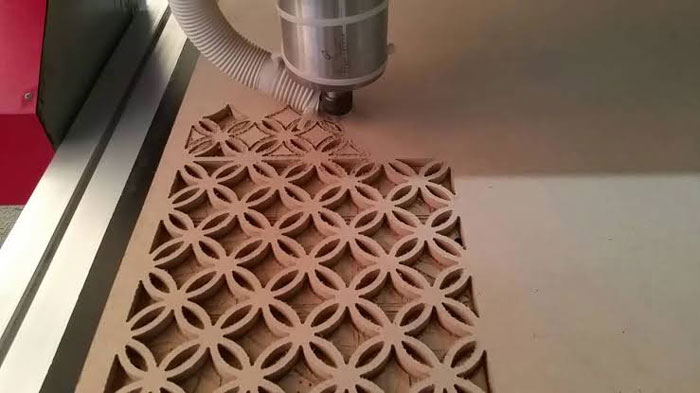

CNC stands for ‘Computer Numerical Control.’ This cutting technique uses a CNC router that is controlled by a computer. Different customers prefer to have their unique designs, so to fulfill their desires, the designers take their ideas first.

After that, they create the same design in a software program (AutoCAD or CorelDRAW). It takes time and accuracy to get the overall blueprint into place because the overall task is computer-oriented. Once they insert the order, everything will set in motion.

Once the professionals are done with the software work, they simply pass the instructions to the computer. It then sends a signal to the router, and then the cutting starts according to the design.

Materials like steel, metal, wood, plastic, etc. can be used for cutting, and the result will be accurate (without a doubt). The significant advantage of applying this technique is that your time will be saved, and there will be no material wastage.

Use a router and table combo just to be on the safer side in case of safety and accuracy.

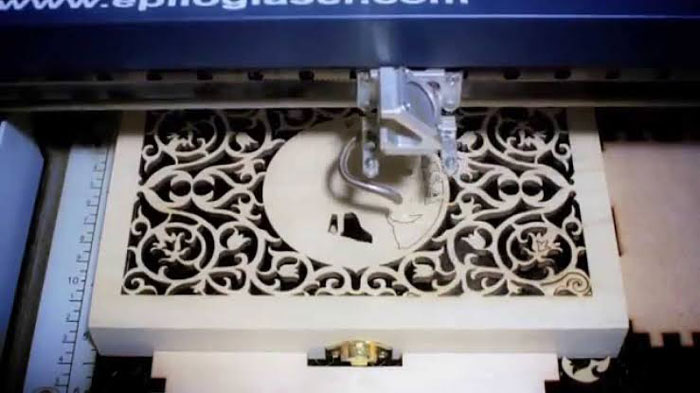

Laser Cutting

This cutting technique possesses the capability to cut the above materials by using a laser mechanism. It uses heat energy to make precise cuts by melting the created path made in the materials. These are very famous in industries due to their top-notch cuts and good quality outputs.

Primary Differences

- CNC cutting uses a CNC router whereas, Laser cutting relies on laser beams.

- There should be a contact between the material and the machine in case of CNC cutting, but for the laser one, you don’t need that and can easily do it from a moderate distance.

- Laser cutting is highly in demand among huge industries. Unfortunately, CNC cutting is not popular in that category, but the good thing is that it is very famous among schools and small enterprises.

- When it comes to cost, Laser cutting is more expensive than the CNC one. People who prefer excellent precision and are not threatened with the price; Laser cutting will be the right choice. Due to that, it remains the first pick among globally renowned industries.

- Because Laser cutting uses heat energy, electricity consumption is huge. As a result, the electricity cost will rise, but CNC cutting requires a minimum power supply to run smoothly.

- Laser cuts provide high accuracy, and the professional won’t need to provide extra physical effort to make sure everything is going perfectly. In the case of CNC cuts, constant moderation is mandatory.

- For welding purposes, the laser cutting technique is the only way to get successful results. The sad news is that CNC cutting won’t be a good choice for this kind of important task.

- The edges of the cuts will always be perfectly sealed in case of laser cutting but not for CNC cutting. The heat energy makes the laser machine a very efficient one, then the CNC.

Conclusion

Pick the best router for the CNC machine. Read the wood router details from the website to get some insights about choosing the right one for you or for anyone.

Get a good quality laser machine for industrial purposes. If you are working in a big industry, use your knowledge from the article and provide a recommendation to the higher management (if necessary).